| 全國24小時咨詢熱線 86-027-89353268 13419620038 |

Wet type granule sizing machine

用途

移動整粒機,把進料口與濕法制粒機出料口對接,開機工作后,濕顆粒在整粒機腔體內,經過整粒刀的撞擊、切割,從篩網孔排出出料口可配真空管道,將物料輸送到沸騰干燥機。

APPLICATION

Move the granulator to dock the feed port with the discharge port of the wet granulator. After the start-up work, the wet granules are in the whole granule cavity, and are punched and cut by the whole knives, discharged from the sieve hole, and the discharge port It can be equipped with a vacuum pipe to deliver the material to the boiling dryer

原理

物料進入到圓錐型篩網腔體內,旋轉刀對物料進行整粒,并使物料顆粒通過篩網孔迅速排出,最終產品排放到整粒機的底部。其轉子可以根據不同物料的性質的需要改變轉速,顆粒大小由篩網孔徑、葉輪類型和轉速決定。形狀分布可通過改變篩網規(guī)格確定。

PRINCIPLE

The material enters the conical mesh cavity, the rotary knife granulates the material, and the material particles are quickly discharged through the mesh hole, and the final product is discharged to the bottom of the granulator. I ne rotor can change the speed according to the nature ot different materials. The particle size is determined by the mesh aperture, impeller type and speed. The shape distribution can be determined by changing the screen size

特點

◆無需其他組件便可安裝在生產線中使用,適用于連線生產。

◆進料和出料漏斗的安裝是由卡箍來完成。具有結構緊湊,使用方便,易清洗的特點。

◆篩網不積料、更換方便。篩網網孔的大小及形狀適應不同物料。

FEATURES

It can be installed in the production line without other components suitable for connection production

The loading and discharge funnels are installed by clamps. It ha characteristics of compact structure, convenient use and easy s the cleaning

The screen is not accumulating and easy to replace The size and shape of the meshmesh are adapted to different materials

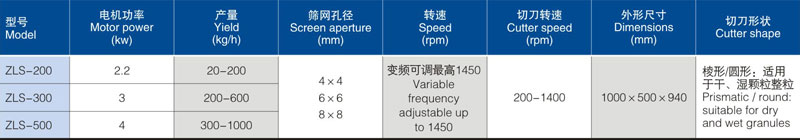

主要技術參數 MAIN TECHNICAL PARAMETERS

本公司可按用戶特殊要求定制生產,如有變動,恕不預先通知!

Our company can customize the products according to special requirements of users. you will not be notified of any changes in advance